|

|

|

|

|

|

Idea

purpose, advantages, inventor

|

|

|

|

|

Research

comminution, material throughput, pressure distribution, modelling

|

|

|

|

|

Praxis

plant configuration, roller wear, references

|

|

|

|

|

|

|

|

Other Links

links to suppliers, universities and other institutions

|

|

|

|

|

Contact

for any questions please contact us

|

|

|

|

|

|

|

|

|

|

|

|

|

Test Methods

|

|

|

|

The material transport in the High Compression Roller Mills can be described with the help of throughput measurements and

by direct observation of the particle movement.

The throughput can be determined easily and is - in an adequately dimensioned mill - only marginally dependent on border

effects. In contrast the observation of the particle movement is limited to the edge zone which is only partially representative for the whole.

|

|

|

|

|

|

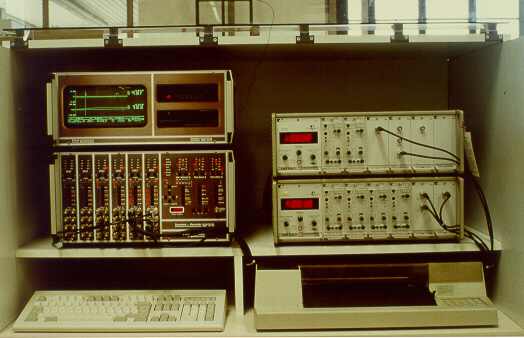

Measuring equipment of a lab-scale High

Compression Roller Mill / Institute for Mineral Processing of the TU Clausthal (Germany, 1989)

|

|

|

The pressure distribution in the compression zone is a characteristic for the stress of the material because by

determination of the maximum pressure the stress intensity can be identified and by integration the energy absorption can be calculated.

The throughput measurements with different roller patterns, recording of particle movements with a video system and the

installation of pressure sensors in the roller shell require a High Compression Roller Mill which constructively meets the following demands of the test method:

simple and quick change of the rollers

facility to install an inspection window for the observation of particle movements

facility to install a pressure sensor in the roller shell

Additionally the measuring technique must facilitate the registration of short-time pressure signals. An experimental

equipment with the necessary options was built by Lubjuhn, U. [25] within the work for his doctoral thesis. The construction of this especially designed lab-scale mill was advised by Dr. Dieter Schwechten during his time as a member of the scientific staff of the Institute for Mineral Processing at the Technical University Clausthal (Germany).

|

|

|

|

|

Comminution

grinding results for different materials

Exper. Setup

lab-scale mill, techn. data mill, intrumentation, feed materials, testing program, roller surface data, test execution

Throughput

literature, decoupling of throughput and comminution, energy absorption, characteristic

of different rollers, phenomenons, throughput results, elasticity, friction angle, specific throughput

Pressure Distribution

pressure diagrams

Press Tests

tests with a molding press

Modelling

mathematic model of the process

Signs and Symbols

nomenclature

|

|

|