|

|

|

|

|

|

Idea

purpose, advantages, inventor

|

|

|

|

|

Research

comminution, material throughput, pressure distribution, modelling

|

|

|

|

|

Praxis

plant configuration, roller wear, references

|

|

|

|

|

|

|

|

Other Links

links to suppliers, universities and other institutions

|

|

|

|

|

Contact

for any questions please contact us

|

|

|

|

|

|

|

|

|

|

|

|

|

Support for the Process Layout of HCRMs

|

|

|

|

Regarding the layout of a roller profile some geometrical thoughts and deductions can be found in the chapter about throughput results.

The layout of a HCRM has to consider planned throughput of the mill or has to ask which throughput can be achieved with

given mill dimensions. The introduction of normalized parameters like throughput number and throughput elasticity as described in the chapter about the compression angle may help to find a mathematical approach to this task.

|

|

|

|

|

|

|

|

Plant Set-up

set-up of grinding circuits with HCRM

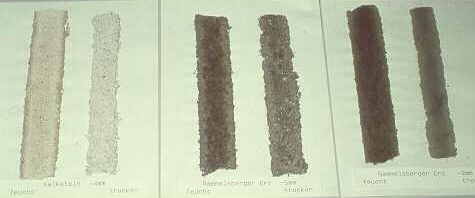

Wear

wear of rollers / roller surfaces

Experiences

publications about the use of HCRMs

Layout

support for process layout of HCRMs

|

|

|